Production method

Solvent Stripping

Place the starting material in a bucket of good depth to prevent the oil solvent mix from splashing out during the washing process. Then, dampen the bud with the solvent being used and then crush the bud material using a length of wood such as a piece of 2×2.

After the bud has been crushed, add more solvent until the bud material is completely immersed in the solvent. Work the bud material for three to four minutes with the length of wood you used to crush it.

Then slowly pour the solvent oil mix off into another clean container, leaving the starting material in the original container, so it can be washed for the second time. To perform the second wash, add fresh solvent to the starting bud material again, until it is once more immersed in the solvent, and then work it for another three to four minutes, with the piece of wood you have been using.

Then, pour the solvent oil mix from the second wash, into the same container that is holding the solvent oil mix from the first wash you did.

Trying to perform a third wash on the remaining plant material, produces very little oil and it would be of much less medicinal value as a medicine. But if you chose to do so the resulting oil from the third wash, could be used to help treat minor problems such as skin conditions.

The first wash dissolves 75 to 80% of the available medicinal resins off the starting material; the second wash then removes most of whatever resin that is of benefit, which remains. Oils produced from the first wash are the most potent medicinally but if high-grade starting material is used, oil from the second wash also has strong medical benefits as well.

If, for some reason, you have to work with material that is not as medicinally active as it should be, it is best to use the oil from the first wash only for internal use and then start to grow, or look for starting material that is of better quality. Remember, quality is more important than quantity and the more medical values the finished oil contains, the better it will work as a medicine.

Strain Bud

Use something such as clean water containers, with a small opening at the top and insert funnels into the openings, then put large coffee filters in the funnels. Pour the solvent oil mix from the first and second washes, into the coffee filters and allow the solvent oil mix to drain into the containers, which are holding the funnels and filters to remove any unwanted plant material etc.

The more funnels and containers you use, the faster the oil solvent mix will be filtered. Once the oil solvent mix has been filtered, it is now ready to have the solvent boiled off. I should also mention that if you are using high quality bud, after the oil solvent mix has been filtered it often looks about the same as gasoline or at times it can be somewhat darker.

Remember that the solvent you are using was clear, so the yellow or darker color the solvent has taken on, is actually due to the healing resins which are now dissolved within it.

Cook Off Solvent

If you do not already own one, you can purchase an inexpensive large rice cooker with an open top that has both high and low heat settings, to boil the solvent off the oil effectively. But make sure that the rice cooker is set up in a well-ventilated area and then place a fan nearby, to blow away the fumes as the solvent boils off.

This will prevent the fumes from condensing and posing a danger. Rice cookers are designed not to burn the rice as it cooks. So the temperature sensors which are built into these devices, will automatically switch the cooker back on the low heat setting, if the temperature within the cooker begins to get too high.

When producing oil, if the temperature gets a little over 300°F (148°C), it will begin to vaporize the cannabinoids off the oil and, of course, you do not want this to occur. If a rice cooker is working properly, it will automatically come off the high heat setting at roughly 210 to 230°F or (100 to110°C), which is above the temperature where most people say decarboxylation is said to occur,

This temperature is still well below the point that THC and other cannabinoids will vaporize off the oil, which remains in the rice cooker. This is why I strongly recommend the use of a rice cooker, to those who have never produced oil before, since it eliminates any danger of harming the oil in question. Plus the resulting oil is decarboxylated, which is also important, so the oil can achieve its full medicinal benefits.

I suggest that people should not try to use crock-pots and similar appliances to produce oil. When I first tried to produce the oil, I used a crock-pot and since I did not know how much heat these devices can generate, the oil overheated and was ruined.

So I think it’s only sensible that a beginner should start out by using a rice cooker and follow my instructions carefully. For by simply doing so, it can save someone new to producing this oil a lot of grief. A distilling device can also be used to produce this medication and reclaim the solvent that is being used. This method really does make more sense than using a rice cooker.

But stills which are designed to boil off solvents safely are expensive and most people, do not know how to operate one of these devices properly. If one is available, I prefer to use a still myself, but, in some countries, owning a still is against the law. If one is serious and wants to produce large amounts of oil, look into distilling and educate yourself in the proper use of this equipment.

Cooking Safety

Always make sure there are no sparks, open flames, or red-hot elements in the area while you are filling the rice cooker or boiling the solvent off, because the fumes produced from solvents are very flammable and quite toxic. I have used this same process hundreds of times and have never had a mishap, but for your own safety, please follow the instructions and make sure the area is well ventilated. I also caution you to avoid breathing in the fumes that solvents produce, since they can have unpleasant effects on anyone nearby.

It is also important to note that some of the airflow from the fan, should be directed towards the bottom of the rice cooker, since fumes from the solvent can often accumulate there. If you look at the bottom of a rice cooker you will find one or two small vents and if the fumes from the solvent enters these vents it could cause a fire.

So I have found that by aiming the airflow from the fan at approximately the center of the rice cooker, the airflow will still carry the fumes from the top of the rice cooker away and will also prevent these fumes from accumulating under the rice cooker at the same time. Make sure that the fan is running and produces enough airflow to blow away the fumes and if you are using a multi speed fan you will probably find that the lower speed settings will accomplish this task.

Then fill the rice cooker until it is about three quarters full of oil solvent mix, this allows room for the oil solvent mix to boil off without splashing over. Place the rice cooker on its high heat setting and then begin boiling the solvent off. Never attempt to do this without the use of a fan, since the solvent fumes could accumulate and if they come into contact with the heating element within the rice cooker, it could cause these fumes to ignite.

Purifying Medicine

As the level in the rice cooker drops, continue to carefully add the solvent oil mix you have remaining, until you have nothing left. When the level in the rice cooker comes down for the last time and has been reduced to about two inches of solvent oil mix remaining. Add about 10 to 12 drops of water to the solvent oil mix, which remains in the rice cooker. This small amount of water allows the remaining solvent, to boil off the oil which remains in the rice cooker more readily and it also helps to cleanse the oil of solvent residue, as the last of the solvent is being boiled off.

When there is very little remaining in the cooker, I usually put on a pair of gloves and then pick up the cooker and begin swirling its contents. This is done with the airflow from the fan still taking the fumes away and it can speed up the finishing process slightly. As the heat within the rice cooker increases, the cooker will automatically switch from the high heat setting and then go to its low heat setting, which prevents the oil within the cooker from overheating.

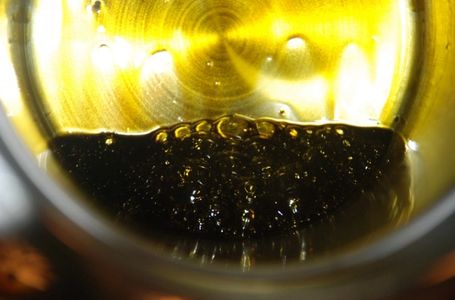

As the last of the solvent is being boiled off, you will hear a crackling sound from the oil that is left in the cooker and you will see quite a bit of bubbling taking place in the oil that remains. Also, you will notice what looks like a small amount of smoke coming off the oil in the rice cooker, but don’t be concerned, since this is mostly just steam produced from the few drops of water that you added.

Finishing Up

After the rice cooker has automatically switched to its low heat setting, I usually let it cool until it can be switched to the high heat setting again. After the cooker has automatically switched itself to the low heat setting for the second time, I then take the inner pot out of the cooker and pour its contents into a stainless steel measuring cup.

I have found that some strains of cannabis can produce an oil, which is actually finished and ready to use after the rice cooker has switched itself to the low heat setting for the second time, but in most cases it is still best the finish the oil properly. There will be a small amount of oil remaining in the pot that you will find almost impossible to get out, unless you use something like dry bread to absorb the oil, while it is still warm. Then, small amounts of this bread can be eaten as a medicine, but remember it can sometimes take an hour or more before you feel its effects.

So be careful about how much bread like this you consume, because even a very small amount may put you to sleep for quite a few hours, just the same as the raw oil will do itself. Another good way to clean up whatever oil remains in the pot, is to wash the pot out with a small amount of alcohol that will absorb the oil, leaving you with a hemp oil tincture, which will vary in medical value depending on how much oil the alcohol now contains.

A tincture such as this can be very effective in the treatment of skin conditions and just a little can go a long way, which can save you money. Since I often liked to mix oil from several strains anyway, I usually leave the remaining oil in the pot until the next time I need to produce the oil. In addition, for those who smoke tobacco and would like to see that much of its harmful effects are removed, then producing what I call happy tobacco should satisfy your needs. All you have to do is heat a small amount of tobacco up in the rice cooker and it will absorb whatever oil is present and then, you should have a substance that will be much less harmful and put you in a better mood when smoked.

By mixing oils from different strains, you receive the medicinal benefits from all these different types of oil and I have found such oils to be effective, in the treatment of just about everything. If you have many different varieties of good cannabis bud at your disposal, I think mixing the oils from different strains of Indica is a good idea, but if you do not, often the oil from just one strain will probably satisfy your needs.

Take the oil that you poured into the stainless steel measuring cup and put it on a gentle heating device such as a coffee warmer to evaporate off whatever water remains in the oil. Quite often, it only takes a short time to evaporate the remaining water off, but also some strains produce more natural terpenes and flavonoids than others. These terpenes and flavonoids can cause the oil you now have on the coffee warmer to bubble for quite some time and it may take a while for such oils to cease this activity.

Syringes

When the oil on the coffee warmer has little or no bubbling activity visible, take the oil off the coffee warmer and allow it to cool a bit, after which it can be drawn up into the plastic syringes for use.

Another way to finish the oil without the use of a coffee warmer, is to put the oil in an oven set at 120°C or about(250°F) for about thirty minutes to an hour. Both of these methods work very well to bring the oil to a finished state.

Then, using plastic applicators or syringes with no needles that should be available from your local drug store, use the plunger of the syringe, to slowly draw the warm oil up into the syringes and then allow it to cool. As the oil comes down to room temperature, the resin or oil which contain the healing cannabinoids, will become a thick grease-like substance and it is then ready to use as a medicine. Sometimes the resin is so thick that it can be hard to force it out of the syringes when cooled. If such a thing happens, simply put the syringe in a cup of hot water, then in a short time you should be able to squeeze your dosage out more easily.

Finished Medicine

There are times when a patient could force too much oil from the syringe, but if this happens, just pull back on the plunger of the syringe and the excess oil can usually be drawn back into the syringe, without too much difficulty. On average, a dry pound of material will require about 2 gallons (8-9 liters) of solvent to do the two washes which are required. If you plan to produce the oil from more or less starting material, simply do the math to determine roughly how much solvent will be needed.

From start to finish, it usually takes three to four hours to accomplish the whole process, and then the medicine is sitting there ready to be used.

It should also be mentioned that this oil has an extremely long shelf life. But for long-term storage, I would put it in a dark bottle with a tight lid or a stainless steel container. If kept in a cool dark place when stored, it can maintain its medicinal potency for a great number of years. At first, it may seem daunting for some to try to produce their own medicine but in reality, this process is extremely simple.

We do not recommend or encourage anyone to produce their own oil, especially in states and areas it is illegal. We are not responsible for anyone conducting such illegal activities with these publicly available instructions. This process can be dangerous if proper safety is not taken. This page is for instructional knowledge on the process of making such a product ONLY. DO NOT PRODUCE IT YOURSELF